DIN6921 Serrated Head Flange Bolt Stainless Steel 304 316

DIN6921 Serrated Head Flange Bolt Stainless Steel 304 316

Tlhaloso

PHAKANGKarabo

PHAKANGQotsulo

PHAKANGPhano

RETS'ELISITSOE HO FIHLELA KEKEPE

10000+ SKU sebakeng sa polokelo

Re ikemiselitse ho etsa lintho tsa RTS:

70% lintho tse fanoeng nakong ea matsatsi a 5

80% lintho tse fanoeng nakong ea matsatsi a 7

90% lintho tse fanoengnakong ea matsatsi a 10

Liodara tse ngata, ka kopo ikopanye le litšebeletso tsa bareki

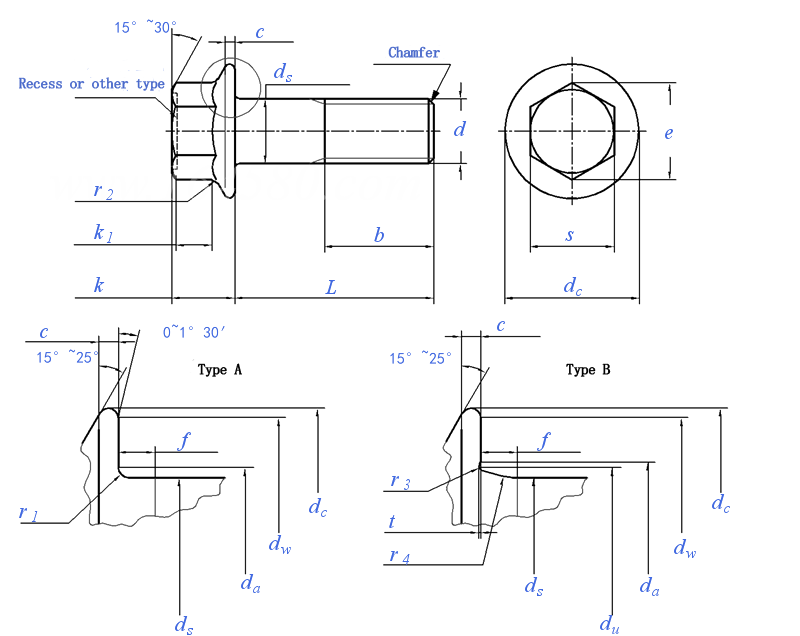

| d | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M20 | ||||

| P | Pitch | E mahoashe | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | ||

| Khoele e ntle1 | / | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 1.5 | ||||

| Khoele e ntle2 | / | / | / | 1 | 1.25 | / | / | / | ||||

| b | L≤125 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 46 | |||

| 125<L≤200 | / | / | 28 | 32 | 36 | 40 | 44 | 52 | ||||

| L~200 | / | / | / | / | / | / | 57 | 65 | ||||

| c | Min | 1 | 1.1 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | |||

| da | Mofuta oa A | Max | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 22.4 | ||

| Mofuta oa B | Max | 6.2 | 7.4 | 10 | 12.6 | 15.2 | 17.7 | 20.7 | 25.7 | |||

| dc | Max | 11.8 | 14.2 | 18 | 22.3 | 26.6 | 30.5 | 35 | 43 | |||

| ds | Max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |||

| Min | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 19.67 | ||||

| du | Max | 5.5 | 6.6 | 9 | 11 | 13.5 | 15.5 | 17.5 | 22 | |||

| dw | Min | 9.8 | 12.2 | 15.8 | 19.6 | 23.8 | 27.6 | 31.9 | 39.9 | |||

| e | Min | 8.71 | 10.95 | 14.26 | 16.5 | 17.62 | 19.86 | 23.15 | 29.87 | |||

| f | Max | 1.4 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | |||

| k | Max | 5.4 | 6.6 | 8.1 | 9.2 | 11.5 | 12.8 | 14.4 | 17.1 | |||

| k1 | Min | 2 | 2.5 | 3.2 | 3.6 | 4.6 | 5.1 | 5.8 | 6.8 | |||

| r1 | Min | 0.25 | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.8 | |||

| r2 | Max | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.9 | 1 | 1.2 | |||

| r3 | Min | 0.1 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | |||

| r4 | ≈ | 3 | 3.4 | 4.3 | 4.3 | 6.4 | 6.4 | 6.4 | 8.5 | |||

| s | Max=Nonomoro | 8 | 10 | 13 | 15 | 16 | 18 | 21 | 27 | |||

| Min | 7.78 | 9.78 | 12.73 | 14.73 | 15.73 | 17.73 | 20.67 | 26.67 | ||||

Tlhaloso e qaqileng

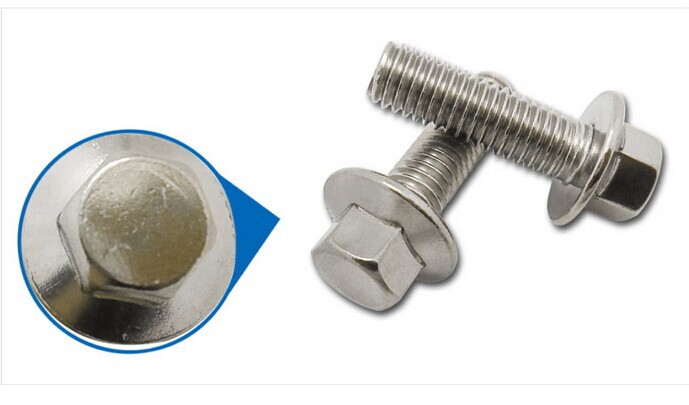

Bolutu ea flange Bolt ea bohlokoa e nang le hlooho ea hexagon le flange (hexagon gasket le hexagon socket e kopantsoeng hammoho) le screw (cylinder e nang le khoele e ka ntle), e lokelang ho kopanngoa le nate ho tiisa karolo e kopanyang likoti tse peli.

1. Mofuta oa hlooho ea hexagonal: e 'ngoe ke hlooho e bataletseng, e' ngoe ke hlooho ea concave.

2. Sehlopha sa 'mala oa bokaholimo: ho latela litlhoko tse fapaneng, bokaholimo bo tletse bosoeu, botala ba sesole, bosehla ba 'mala, Dacromet e hanyetsanang le kutu.

3, mofuta oa flange: ho latela ts'ebeliso ea liboutu tsa flange maemong a fapaneng, boholo ba litlhoko tsa disk li fapane, hape ho na le tlase tlase le serrated, leino le nang le phello e khahlanong le ho thella.

4. Ho ea ka mokhoa oa matla oa ho hokahanya, ho na le masoba a tloaelehileng le a hinged. Li-flange bolts bakeng sa masoba a ho tsosolosa li lokela ho lumellana le boholo ba likoti 'me li sebelisoe ha li le tlas'a matla a ho pota-pota.

Ho phaella moo, e le ho finyella litlhoko tsa ho koala ka mor'a ho kenya, ho na le likoti likarolong tsa molamu, tse ka etsang hore liboutu li se ke tsa hlephile ha li tlas'a vibration.

Liboutu tse ling tsa flange ha li na khoele ea karolo e se nang letho eo u ka e etsang, e bitsoang liboutu tse tšesaane tsa flange. Mofuta ona oa flange bolt o thusa ho kopanya tlas'a matla a fapaneng.

Flange bolt e entsoe ka hexagonal hlooho le poleiti ea flange, "sebaka sa ts'ehetso sa sebaka sa khatello ea maikutlo" se seholo ho feta bolt e tloaelehileng, kahoo bolt ena e ka jara preload e phahameng, ts'ebetso ea anti-loose e boetse e betere, ka hona e sebelisoa haholo lienjineng tsa likoloi, mochini o boima le lihlahisoa tse ling.

Ho paka

Mabapi le rona

* Setšoantšo se latelang se bontša li-incoterms tse fapaneng tsa khoebo. Ka kopo, khetha eo u e ratang.

SEHLAHISO SE TLOSO

Boleng ba Pele, Tšireletseho e Tiisitsoe