DIN7991 Hex Socket Countersunk Screw Kereite ya Carbon Steel Zinc Plated Kereiti ya 8.8 10.9

DIN7991 Hex Socket Countersunk Screw Kereite ya Carbon Steel Zinc Plated Kereiti ya 8.8 10.9

Tlhaloso

PHAKANGKarabo

PHAKANGQotsulo

PHAKANGPhano

RETS'ELISITSOE HO FIHLELA KEKEPE

10000+ SKU sebakeng sa polokelo

Re ikemiselitse ho etsa lintho tsa RTS:

70% lintho tse fanoeng nakong ea matsatsi a 5

80% lintho tse fanoeng nakong ea matsatsi a 7

90% lintho tse fanoengnakong ea matsatsi a 10

Liodara tse ngata, ka kopo ikopanye le litšebeletso tsa bareki

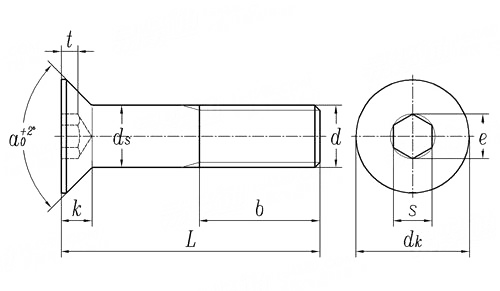

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Pitch | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | tol.(+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125 limilimithara | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125<L ≤200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L~200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Max=Nonomoro | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Max=Nonomoro | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Lebitso | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Max=Nonomoro | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

Tlhaloso e qaqileng

Li-fasteners tse matla tse phahameng li tla hlahisa crispness ha li entsoe ka galvanized. Hloka tlhokomelo e khethehileng.

Hydrogen embrittlement hangata e tšoauoa ka ho lieha ho robeha tlas'a khatello ea maikutlo. Ho bile le liliba tsa likoloi, li-washer, li-screw, li-sheet springs le likarolo tse ling tse entsoeng ka masenke, ka mor'a lihora tse 'maloa ka mor'a hore kopano e robehe, karolo ea 40% ~ 50% e robehile. Ts'ebetsong ea ho sebelisa likarolo tse entsoeng ka cadmium tsa sehlahisoa se khethehileng, ho ne ho e-na le ho robeha ha batch crack, 'me bothata ba senotlolo sa naha bo ile ba rarolloa' me ha etsoa mokhoa o tiileng oa dehydrogenation. Ho phaella moo, ho na le ba bang ba embrittlement haedrojene ha e bontše lieha ho robeha ketsahalo, tse kang: electroplating hanger (tšepe terata, terata koporo) ka lebaka la makhetlo a mangata a electroplating le pickling plating, ho kenella ka hydrogen ke tse tebileng haholoanyane, hangata hlaha ka tšebeliso lesaka tla etsahala brittle fracture ketsahalo; Mandrel ea sethunya, ka mor'a makhetlo a 'maloa a chroming, a oela fatše' me a robeha; Likarolo tse ling tse tingoeng (khatello e kholo ea ka hare) li tla peperana ha ho khethoa. Likarolo tsena li na le hydrogenated haholo 'me li phunyeha ntle le khatello ea kelello e ka ntle, e ke keng ea hlola e sebelisoa ho tsosolosa boima ba pele ka dehydrogenation.

Ha matla a thepa a phahame, ho ba le kutloisiso e kholo ea hydrogen embrittlement. Ena ke mohopolo oa mantlha o tlamehang ho hlakisoa ke litsebi tsa kalafo ea holim'a metsi ha li hlophisa lintlha tsa ts'ebetso ea electroplating. Litšepe tse nang le matla a thata a σb> 105kg/mm2 tse hlokoang ke litekanyetso tsa machaba li lokela ho ba tlas'a khatello ea pele ea ho pata le kalafo ea post-plating dehydrogenation ho latela. Indasteri ea lifofane ea Fora e hloka kalafo e tsamaellanang ea dehydrogenation bakeng sa likarolo tsa tšepe tse nang le matla a tlhahiso σs> 90kg/mm2.

Ka lebaka la ngollano e ntle pakeng tsa matla a tšepe le boima, ho bonolo ebile ho bonolo ho ahlola kutloisiso ea hydrogen embrittlement ea lintho tse bonahalang ka thatafalloa ho feta ka matla. Hobane setšoantšo se phethahetseng sa sehlahisoa le ts'ebetso ea machining e lokela ho tšoauoa ka thata ea tšepe. Ka electroplating, re fumane hore ho thatafala ha tšepe ho pota-pota HRC38 ho qalile ho bontša kotsi ea ho robeha ha hydrogen embrittlement. Bakeng sa likarolo tse phahameng ho feta HRC43, dehydrogenation e lokela ho nahanoa ka mor'a ho rala. Ha boima bo ka ba HRC60, kalafo ea dehydrogenation e tlameha ho etsoa hang ka mor'a ho phekola holimo, ho seng joalo likarolo tsa tšepe li tla peperana ka mor'a lihora tse 'maloa.

Ho paka

Mabapi le rona

* Setšoantšo se latelang se bontša li-incoterms tse fapaneng tsa khoebo. Ka kopo, khetha eo u e ratang.

TLHOKOMELO E TLOANG

Boleng ba Pele, Tšireletseho e Tiisitsoe