DIN912 H59 H62 Brass Hex Socket Cup Screw ea Hlooho

DIN912 H59 H62 Brass Hex Socket Cup Screw ea Hlooho

Tlhaloso

PHAKANGKarabo

PHAKANGQotsulo

PHAKANGPhano

RETS'ELISITSOE HO FIHLELA KEKEPE

10000+ SKU sebakeng sa polokelo

Re ikemiselitse ho etsa lintho tsa RTS:

70% lintho tse fanoeng nakong ea matsatsi a 5

80% lintho tse fanoeng nakong ea matsatsi a 7

90% lintho tse fanoengnakong ea matsatsi a 10

Liodara tse ngata, ka kopo ikopanye le litšebeletso tsa bareki

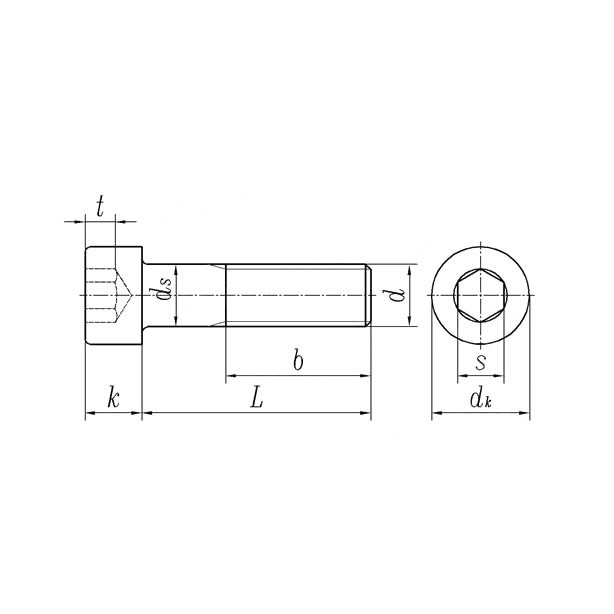

| d | M1.4 | M1.6 | M2 | M2.5 | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | |

| P | Khoele e mahoashe | 0.3 | 0.35 | 0.4 | 0.45 | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 |

| Khoele e ntle | / | / | / | / | / | / | / | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 2 | 2 | |

| Khoele e ntle haholo | / | / | / | / | / | / | / | / | / | 1 | 1.25 | / | / | 1.5 | 1.5 | |

| b | Reference value | 14 | 15 | 16 | 17 | 18 | 20 | 22 | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 |

| dk | Max (Boreleli) | 2.6 | 3 | 3.8 | 4.5 | 5.5 | 7 | 8.5 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 |

| Max (Knurl*) | 2.74 | 3.14 | 3.98 | 4.68 | 5.68 | 7.22 | 8.72 | 10.22 | 13.27 | 16.27 | 18.27 | 21.33 | 24.33 | 27.33 | 30.33 | |

| Min | 2.46 | 2.86 | 3.62 | 4.32 | 5.32 | 6.78 | 8.28 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.67 | 29.67 | |

| ds | Max | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | |

| k | Max | 1.4 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 |

| Min | 1.26 | 1.46 | 1.86 | 2.36 | 2.86 | 3.82 | 4.82 | 5.7 | 7.64 | 9.64 | 11.57 | 13.57 | 15.57 | 17.57 | 19.48 | |

| s | Lebitso | 1.3 | 1.5 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 14 | 17 |

| Min | 1.32 | 1.52 | 1.52 | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 12.032 | 14.032 | 14.032 | 17.05 | |

| Max | 1.36 | 1.56 | 1.56 | 2.06 | 2.58 | 3.08 | 4.095 | 5.14 | 6.14 | 8.175 | 10.175 | 12.212 | 14.212 | 14.212 | 17.23 | |

| t | Min | 0.6 | 0.7 | 1 | 1.1 | 1.3 | 2 | 2.5 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Bolelele ba khoele=b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| d | (M22) | M24 | (M27) | M30 | (M33) | M36 | M42 | M48 | M56 | M64 | M72 | M80 | M90 | M100 | |

| P | Khoele e mahoashe | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6 | 6 | 6 | 6 | 6 |

| Khoele e ntle | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 4 | 4 | |

| Khoele e ntle haholo | 1.5 | / | / | / | / | / | / | / | / | / | / | / | / | / | |

| b | Reference value | 56 | 60 | 66 | 72 | 78 | 84 | 96 | 108 | 124 | 140 | 156 | 172 | 192 | 212 |

| dk | Max (Boreleli) | 33 | 36 | 40 | 45 | 50 | 54 | 63 | 72 | 84 | 96 | 108 | 120 | 135 | 150 |

| Max (Knurl*) | 33.39 | 36.39 | 40.39 | 45.39 | 50.39 | 54.46 | 63.46 | 72.46 | 84.54 | 96.54 | 108.54 | 120.54 | 135.63 | 150.63 | |

| Min | 32.61 | 35.61 | 39.61 | 44.61 | 49.61 | 53.54 | 62.54 | 71.54 | 83.46 | 95.46 | 107.46 | 119.46 | 134.37 | 149.37 | |

| ds | Max | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 |

| Min | 21.67 | 23.67 | 26.67 | 29.67 | 32.61 | 35.61 | 41.61 | 47.61 | 55.54 | 63.54 | 71.54 | 79.54 | 89.46 | 99.46 | |

| k | Max | 22 | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 56 | 64 | 72 | 80 | 90 | 100 |

| Min | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 41.38 | 47.38 | 56.26 | 63.26 | 71.26 | 79.26 | 89.13 | 99.13 | |

| s | Lebitso | 17 | 19 | 19 | 22 | 24 | 27 | 32 | 36 | 41 | 46 | 55 | 65 | 75 | 85 |

| Min | 17.05 | 19.065 | 19.065 | 22.065 | 24.065 | 27.065 | 32.08 | 36.08 | 41.08 | 46.08 | 55.1 | 65.1 | 75.1 | 85.12 | |

| Max | 17.23 | 19.275 | 19.275 | 22.275 | 24.275 | 27.275 | 32.33 | 36.33 | 41.33 | 46.33 | 55.4 | 65.4 | 75.4 | 85.47 | |

| t | Min | 11 | 12 | 13.5 | 15.5 | 18 | 19 | 24 | 28 | 34 | 38 | 43 | 48 | 54 | 60 |

| Bolelele ba khoele=b | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

Tlhaloso e qaqileng

Phapano ke efe lipakeng tsa Koporo, Koporo, Boronse?

Koporo, Brass le Bronze, tse tsejoang e le "Red Metals", li ka shebahala li tšoana qalong. Empa ehlile ba na le phapang e ngata ho element, ts'ebetso joalo-joalo.

Koporo

Koporo e sebelisoa mefuteng e mengata ea lihlahisoa ka lebaka la motlakase o motle oa motlakase le oa mocheso, matla a matle, sebopeho se setle le ho hanyetsa ho bola. Lisebelisoa tsa liphaephe le liphaephe li atisa ho etsoa ka litšepe tsena ka lebaka la ho hanyetsa ha tsona. Li ka rekisoa habonolo le ho chesoa, 'me tse ngata li ka chesoa ka mefuta e fapaneng ea khase, arc le mekhoa ea ho hanyetsa. Li ka belisoa 'me tsa khabisoa hoo e batlang e le sebopeho leha e le sefe se lakatsehang le ho benya.

Ho na le limaraka tsa koporo e sa alloeng, 'me li ka fapana ho ea ka bongata ba litšila tse teng. Limaraka tsa koporo tse se nang oksijene li sebelisoa ka ho khetheha mesebetsing eo ho eona ho hlokahalang conductivity e phahameng le ductility.

E 'ngoe ea thepa ea bohlokoa ka ho fetisisa ea koporo ke bokhoni ba eona ba ho loantša libaktheria. Ka mor'a tlhahlobo e pharaletseng ea likokoana-hloko ke Setsi sa Tšireletso ea Tikoloho, ho ile ha fumanoa hore li-alloys tsa koporo tse 355, ho kenyeletsa le li-brasses tse ngata, li fumanoe li bolaea ho feta 99.9% ea libaktheria nakong ea lihora tse peli tsa ho kopana. Ho silafala ho tloaelehileng ho fumanoe hore ha ho senye katleho ea antimicrobial.

Lisebelisoa tsa Koporo

Koporo e ne e le e 'ngoe ea litšepe tsa pele tse ileng tsa sibolloa. Bagerike le Baroma ba ile ba e etsa lithulusi kapa mekhabiso, ’me ho na le lintlha tsa histori tse bontšang ho sebelisoa ha koporo ho ntša maqeba maqeba le ho hloekisa metsi a nooang. Kajeno hangata e fumanoa linthong tsa motlakase tse kang wiring ka lebaka la bokhoni ba eona ba ho tsamaisa motlakase ka katleho.

Koporo

Brass haholo-holo ke motsoako o nang le koporo e nang le zinki e kentsoeng. Li-brasses li ka ba le mefuta e fapaneng ea zinki kapa likarolo tse ling tse ekelitsoeng. Metsoako ena e fapaneng e hlahisa mefuta e mengata ea thepa le mefuta e fapaneng ea mebala. Keketseho ea zinki e fana ka thepa ka matla a ntlafetseng le ductility. Brass e ka fapana ka 'mala ho tloha bofubelu ho ea ho mosehla ho itšetlehile ka palo ea zinki e kentsoeng ho motsoako.

Haeba lihlahisoa tsa zinki tsa koporo li tloha ho 32% ho ea ho 39%, li tla be li ekelitse bokhoni ba ho sebetsa ka mocheso empa ho sebetsa ha serame ho tla fokotseha.

Haeba koporo e na le zinki tse fetang 39% (mohlala - Muntz Metal), e tla ba le matla a phahameng le ho fokotsa ductility (mocheso oa kamore).

Lisebelisoa tsa Brass

Brass e atisa ho sebelisoa bakeng sa merero ea ho khabisa haholo-holo ka lebaka la ho tšoana ha eona le khauta. Ho ke ke e boetse e ka tloaelo sebelisoa ho etsa liletsa tsa 'mino ka lebaka la ho workability phahameng le durability.

Boronse

Bronze ke motsoako o nang le koporo haholo-holo ka ho eketsoa ha lisebelisoa tse ling. Hangata motsoako o eketsoang ke tin, empa arsenic, phosphorus, aluminium, manganese, le silicon le tsona li ka sebelisoa ho hlahisa thepa e fapaneng ea thepa. Lisebelisoa tsena kaofela li hlahisa motsoako o thata haholo ho feta koporo feela.

Bronze e khetholloa ka 'mala oa eona o lerootho oa khauta. U ka boela ua tseba phapang pakeng tsa boronse le koporo hobane boronse e tla ba le mehele e fokolang holim'a eona.

Lisebelisoa tsa Bronze

Bronze e sebelisoa kahong ea litšoantšo tse betliloeng, liletsa tsa 'mino le likhau, le lits'ebetsong tsa indasteri tse kang li-bushings le li-bearings, moo tšepe ea eona e tlaase holim'a tšepe ea tšepe e leng molemo. Bronze e boetse e na le lisebelisoa tsa metsing ka lebaka la ho hanyetsa ha eona ho bola.

Ho paka

Mabapi le rona

* Setšoantšo se latelang se bontša li-incoterms tse fapaneng tsa khoebo. Ka kopo, khetha eo u e ratang.

TLHOKOMELO E TLOANG

Boleng ba Pele, Tšireletseho e Tiisitsoe