ISO7380 Stainless Steel Hex Socket Pan Head Screw SUS304 SUS316

ISO7380 Stainless Steel Hex Socket Pan Head Screw SUS304 SUS316

Tlhaloso

PHAKANGKarabo

PHAKANGQotsulo

PHAKANGPhano

RETS'ELISITSOE HO FIHLELA KEKEPE

10000+ SKU sebakeng sa polokelo

Re ikemiselitse ho etsa lintho tsa RTS:

70% lintho tse fanoeng nakong ea matsatsi a 5

80% lintho tse fanoeng nakong ea matsatsi a 7

90% lintho tse fanoengnakong ea matsatsi a 10

Liodara tse ngata, ka kopo ikopanye le litšebeletso tsa bareki

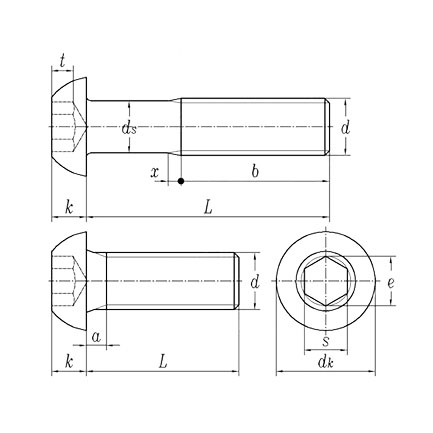

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | M16 | |

| P | Pitch | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 |

| a | Max | 1 | 1.4 | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 |

| Min | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | |

| dk | Max | 5.7 | 7.6 | 9.5 | 10.5 | 14 | 17.5 | 21 | 28 |

| Min | 5.4 | 7.24 | 9.14 | 10.07 | 13.57 | 17.07 | 20.48 | 27.48 | |

| e | Min | 2.303 | 2.873 | 3.443 | 4.583 | 5.723 | 6.863 | 9.149 | 11.429 |

| k | Max | 1.65 | 2.2 | 2.75 | 3.3 | 4.4 | 5.5 | 6.6 | 8.8 |

| Min | 1.4 | 1.95 | 2.5 | 3 | 4.1 | 5.2 | 6.24 | 8.44 | |

| s | Lebitso | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 |

| Max | 2.08 | 2.58 | 3.08 | 4.095 | 5.14 | 6.14 | 8.175 | 10.175 | |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | |

| t | Min | 1.04 | 1.3 | 1.56 | 2.08 | 2.6 | 3.12 | 4.16 | 5.2 |

| Bonyane boima ba tsitsipano(N) | 8.8Kereiti | 3220 | 5620 | 9080 | 12900 | 23400 | 37100 | 53900 | 100000 |

| 10.9 Kereiti | 4180 | 7300 | 11800 | 16700 | 30500 | 48200 | 70200 | 130000 | |

| 12.9 Kereiti | 4910 | 8506 | 13800 | 19600 | 35700 | 56600 | 82400 | 154000 | |

Tlhaloso e qaqileng

Round Head Hex Socket Head Screw ke eng?

Tekanyetso ea Round Head Hex Socket Head Screw ke ISO 7380. Tlhaloso ea hexagon socket flat round head screw e bolela sekurufu se nang le sokete ea hexagon le hlooho e sephara e chitja. Lebitso la profeshenale la indasteri ea li-screw le bitsoa kopi e bataletseng, e leng kakaretso e batlang e le bonolo. E boetse e bitsoa hexagon socket round cup, socket socket flat head bolt. Ho na le mabitso a mangata, empa litaba li tšoana.

Ho na le mefuta e 'meli ea lisebelisoa bakeng sa li-screw tsa hexagon socket head dome. Tsena tse peli ke lisebelisoa tse sebelisoang hangata, ho kenyelletsa tšepe e sa hloekang le tšepe ea carbon. Bakeng sa tšepe ea carbon, hangata re bua ka tšepe. Tšepe ea carbon e arotsoe ka lihlopha tsa boima, ho kenyelletsa le tšepe e tlaase ea carbon. Tšepe ea khabone e mahareng le tšepe e phahameng ea khabone. Ka hona, limaraka tsa matla tsa li-screw tsa hexagon socket head cap ke 4.8, 8.8, 10.9, le 12.9.

Haeba sekoti sa hexagon socket head flat head screw ke tšepe, hangata se hloka ho etsoa electroplated. Electroplating e arotsoe ka ts'ireletso ea tikoloho le ts'ireletso e seng ea tikoloho. Tšireletso e seng ea tikoloho ke electroplating e tloaelehileng. Tse nang le botsoalle ho tikoloho li kenyelletsa zinki e putsoa e nang le tikoloho, zinki e mebala-bala ea tikoloho, nickel e nang le botsoalle ba tikoloho, le zinki tse tšoeu tse nang le tikoloho, joalo-joalo. Electroplating e seng ea tikoloho e kenyelletsa zinki e ntšo, zinki tse tšoeu, zinki tsa 'mala, nickel e tšoeu, nickel e ntšo, le cladding e ntšo.

Ho paka

Sephutheloana sa li-screws tsa socket head cap ke lebokose le lebokose le ka ntle ka ho sa feleng.

Mabapi le rona

* Setšoantšo se latelang se bontša li-incoterms tse fapaneng tsa khoebo. Ka kopo, khetha eo u e ratang.

TLHOKOMELO E TLOANG

Boleng ba Pele, Tšireletseho e Tiisitsoe